Anti-vibration and Self-lubricating bushings

We have invented and developed different types of anti-vibration bushings with unique features and high technological content.

The quality of our articles has allowed us to expand toward foreign markets, in fact there is a demand for our bushings at an international level, in particular for the automotive industry.

KEY APPLICATIONS

Leaf springs

Pneumatic suspensions

Swing arms

Shakel

The SAV anti-vibration bushings

Our anti-vibration bushings have several features that make them totally unique:

- They are self-lubricating;

- They are developed using the Easy FIT technology;

- They are lighter in weight;

- They guarantee less noise;

- They guarantee longer duration;

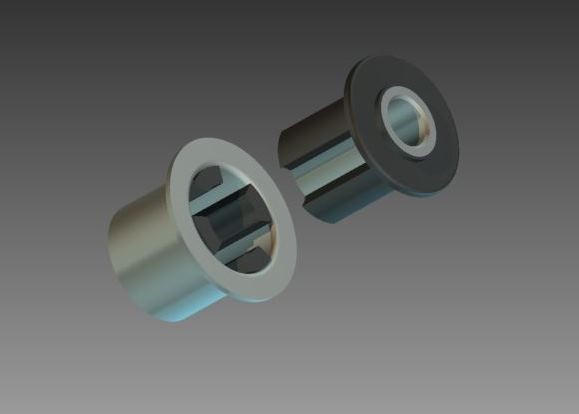

Type I and II sliding bushings - SAV patented

Our Type I and II sliding bushings have been patented with a material we created ourselves and we export them worldwide: Movelon®.

The bushings are self-lubricating and are designed for swing arms and leaf springs. They have low coefficient friction, making it possible to eliminate torsional stress.

They can be mounted on unprocessed eyes, saving on processing costs.

The article is designed for the characteristics of specific vehicles such as FIAT Ducato.

Sliding bushings with Movelon®

Our sliding bushings with Movelon® are designed for use on swing arms. They are characterised by a low friction coefficient and by the elimination of torsional stress, with a consequent and considerable increase in service life under stress.

These specific anti-vibration bushings have also been designed to maintain excellent axial and pendular suspension.

The article is designed and engineered for the characteristics of specific vehicles.

Bushings and half-bushings with camber - SAV patented

Our rubber – metal – nylon anti-vibration bushings are SAV patented and designed to allow both extensive torsional movements and high resistance against axial and radial loads.

They adapt to the vehicle suspensions, articulated arms and all types of linkage systems.

Possible applications for rubber anti-vibration bushings are:

- leaf springs;

- pneumatic suspensions;

- swing arms;

- shackel.

Interlocking bushings - SAV patented

Our SAV patented high strength rubber metal bushings are designed to withstand significant torsional, radial and axial stress.

Thanks to the design and engineering of a particular structure they are significantly more fatigue-resistant than traditional metal rubber bushings.

Possible applications for rubber metal bushings are:

- leaf springs;

- pneumatic suspensions;

- swing arms;

Metal rubber bushings and half-bushings with or without inner reinforcement

The metal rubber bushings consist of two tubes chemically coupled by a vulcanised rubber thickness, which has high mechanical strength features.

These anti-vibration bushings are used as a coupling for moving parts, such as joints, flexible couplings, articulations or compensation elements. They can be stressed in a radial, axial and torsional direction; allowing deformation depending on the hardness of the rubber, without the rubber detaching from the metal.

As for the customisation of metal rubber bushings, we recommend that you inform us of the type of application and the characteristics of use in order so our technical team can provide personalised optimisation recommendations.

Generally speaking, the assembly of the outer tube is achieved by forcing it into its seat; while the inner tube is bolted to the bracket.

Polyurethane bushings

We also use polyurethane for our anti-vibration bushings because it has various characteristics that allow us to produce quality products. Our polyurethane bushings have excellent resistance at both high and low temperatures, a low specific weight and low friction coefficient.

Possible applications for our polyurethane bushings are:

- stabiliser bars;

- links.